Bales everywhere.

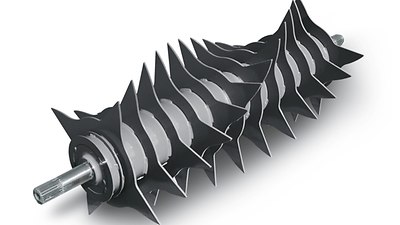

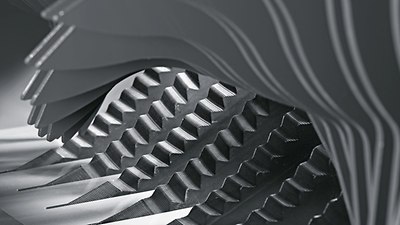

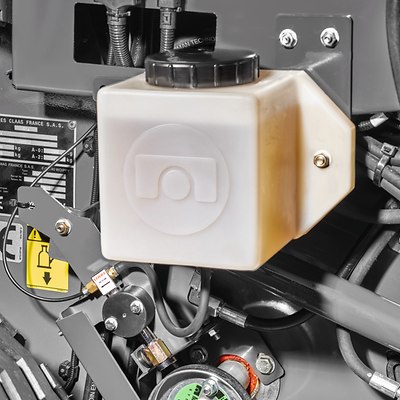

Robustness and reliability under the toughest operating conditions have made the ROLLANT the best-selling silage baler in the world. Reinforced rollers, intelligent chain lubrication and the optional MAXIMUM PRESSURE SYSTEM (MPSII) in the tailgate ensure that it stays that way.